2024

Flow-Liner’s CIP-Conduit

Conduit pipes are typically encased in concrete. Encasing a conduit in concrete will provide strength to the existing asset and will provide added protection to the conduit from unexpected external load and movement, reducing the risk of damage and the need for repairs. It also aids in protecting the conduits against liquid infiltration. A customer in Arizona was having some problems with their electrical conduits. After televising, the issue was quite clear - during the encasement process, the conduits had separated, allowing concrete to fill the conduit. To avoid breaking up the entire concrete encasement and start the project over, a Flow-Liner Certified Installer was contacted.

The Flow-Liner Certified Installer's first and most challenging objective was removing ten feet of cement from the conduit with a robotic cutter in a location that was over 100 feet in from the access point. Once the conduit was cleared and cleaned, the CIP-Conduit process could begin. The installer successfully lined approximately 140 feet of conduit -leaving them with a happy customer. CIP-Conduit® (Cured-In-Place Conduit) can be designed and installed according to your specifications and needs for underground conduits. A pre-site evaluation may be performed by one of our trained and Certified Installers. Once the necessary information is gathered, it is submitted to our Technical Design Division. Lining options will be submitted for customer review and approval.

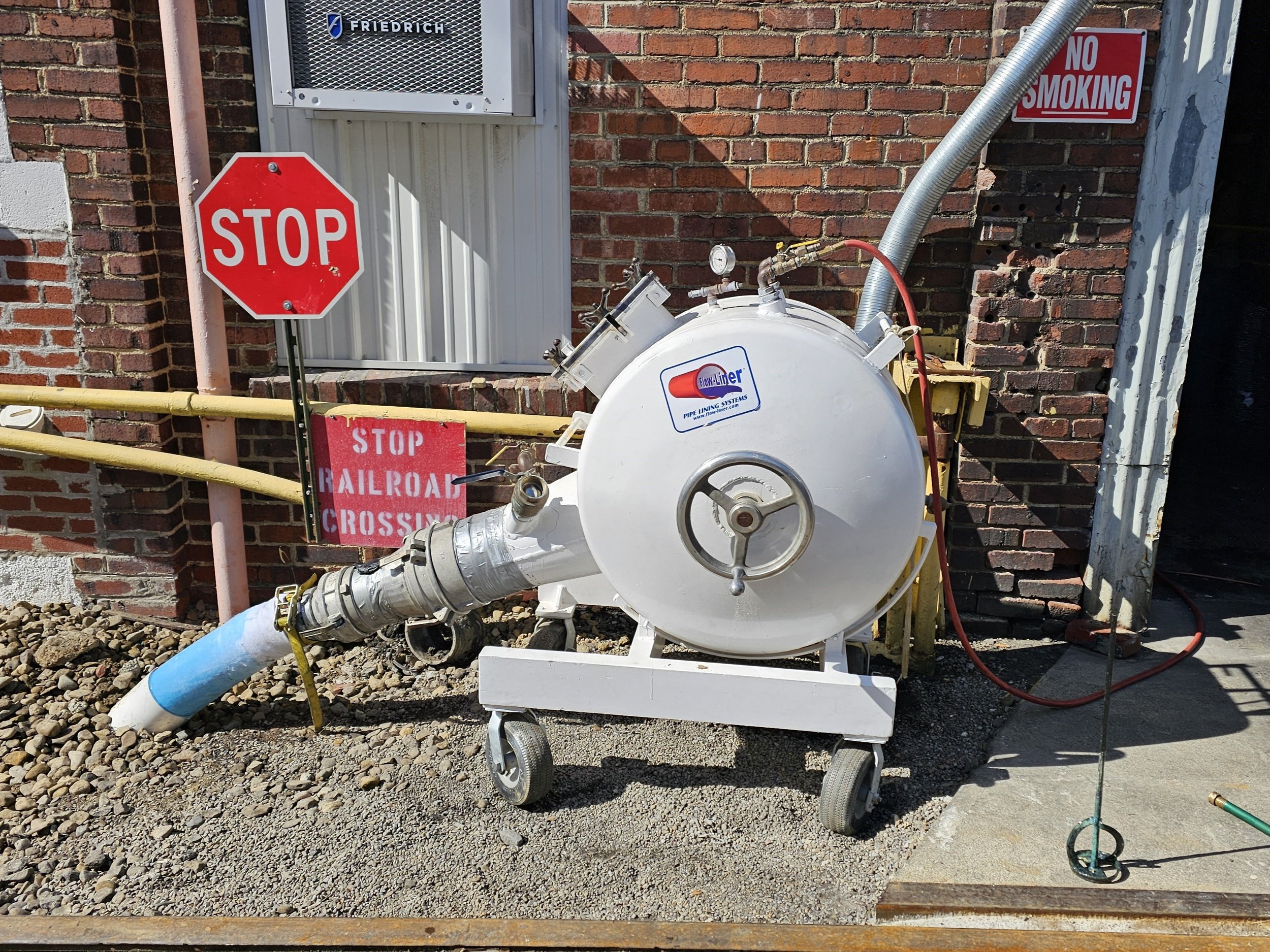

CIPP at Holophane of Newark, Ohio

Holophane provides industry-leading lighting products and solutions, giving their customers the greatest value through improved visibility, energy efficiency, reliability, quality and service. Holophane has been providing indoor and outdoor lighting customers with solutions that meet or exceed a whole host of demanding challenges for over 125 years. Holophane's Newark, Ohio location discovered a need for trenchless technology and contacted a Flow-Liner Certified Installer.

Finding the Issue: After televising, the Flow-Liner Certified Installer identified the issue - several locations along a 6" clay tile pipe were cracked. After fixing a problematic branch line, they installed a new cleanout and proceeded to the next steps - cleaning the pipe and installing cured-in-place-pipe (CIPP).

Solving the Problem: The Flow-Liner Certified Installer was able to successfully utilize CIPP lining to seal all cracks along the 80 feet of clay tile pipe, navigating one bend and reinstating three branch lines along the way. Holophane was very happy to avoid digging up 80 feet of pipe.